Motoman MIG MAG arc welding robotic system consisting of:

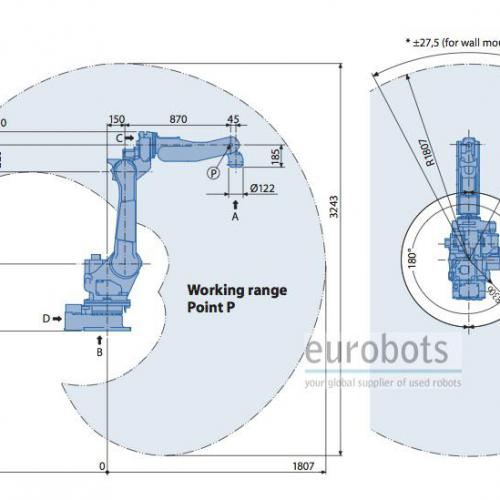

- 2 x Motoman EA1800n industrial robot, 6 axis, 6 kg payload, 1807 mm horizontal arm reach and 0.08 mm accuracy in repeatability. Special design arc welding robot with hollow wrist to improve manouveranility.

- 2 x Motoman NX100 controllers, one of them controlling 9 axis, six for the robot and three additional for the positioner

- 1 x Motoman 3 axis H shape RM positioner, with a payload of 500 kg. Two station with central horizontal servocontrolled rotary axis which automatically switches load and unload stations. On each station distance of 2000 mm between head and tailstock

- 2 x Fronius TPS4000 Synergic power source, liquid cooled, 400 Amperes power

- 2 x Fronius welding torches with anticolision, liquid cooled

- 2 x torch cleaning station

Faster, feature-packed, highly reliable and easier to use - Motoman's new NX100 robot control system has arrived. NX100 is the PC-based high performance robot controller.

The NX100 controller features a Windows® CE programming pendant with full colour LCD touch screen display. It offers high speed processing, unmatched memory (60,000 steps, 10,000 instructions), built-in ethernet and a robust PC-architecture.

The NX100 easily handles multiple tasks and can control up to four robots plus external axes (max 36 axes) and I/O devices. Advanced Robot Motion control (ARM) provides high performance path accuracy and motion control.

The control system's PC architecture offers unlimited communication with other systems via a wide range of communication protocols. The improved integrated PLC will in many cases eliminate the need for a separate PLC, saving costs at the system level.

Multiple robot control

Real time synchronisation of up to four robots and external axes (max.36 axes)

- Jigless welding possible

- Enables high density robot layouts

- Reduced cycle times

- User friendly touch screen pendant

With Windows CE operating system and a full colour LCD touch-screen display

- Complete access tto all operations from programming to maintenance

- Reduced programming time

- Possibility to create your own user menus

- Eliminates the need for separate operator's panel

Advanced robot motion (ARM) control

Dynamic calculation of robot axis torque and loan (an original Motoman development)

- High performance path accuracy

- Optimised robot motion & speed

- Short pitch function

- Collision detection

Communication features

Built-in Ethernet;Web, FTP and OPC server options

Fieldbus support of the 15 most common brands on the market

- Easy to connect to existing networks

- Remote monitoring and diagnostics of robot systems

Robot main features

- Maximum Load of Robot: 15 Kg

- Maximum Reach: 1807 mm

- Repeatability: 0.08 mm

- Controller: NX100

Robot Motion Speed

- Axis S: 195º/s

- Axis L: 170º/s

- Axis U: 175º/s

- Axis R: 340º/s

- Axis B: 340º/s

- Axis T: 520º/s

Motion range

- Axis S: +-180º/s

- Axis L: +155º,-100º

- Axis U: +210º,-175º

- Axis R: +-175º

- Axis B: +-180/-45º

- Axis T: +-200º

Funções

Fotos

Diagramas